The damage to ropes, slings, and PPE from UV due to their daily exposure to hot weather conditions puts heat stress on more than just the personnel climbing the towers. According to Kathy Gill, President and Founder of Tower Safety, the deadly combination of long term exposure and the material choices for climbing gear can turn a brutally hot day into a dangerous one.

“The ropes should have the additives or fibers to mitigate the UV effects as much as possible,” Gill said. “But all of it, harnesses, ropes and rigging slings, can degrade with UV damage.”

According to Mike Riggs, the president of the Rigging Institute™, the most common cause of a synthetic sling failure is due to cutting or UV degradation. ASME B30.9-5.9.4 Removal Criteria states: “A synthetic webbing sling shall be removed from service if conditions such as the following are present:(d) holes, tears, cuts, or snags…(h) discoloration and brittle or stiff areas on any part of the sling, which may mean chemical or ultraviolet/sunlight damage.”

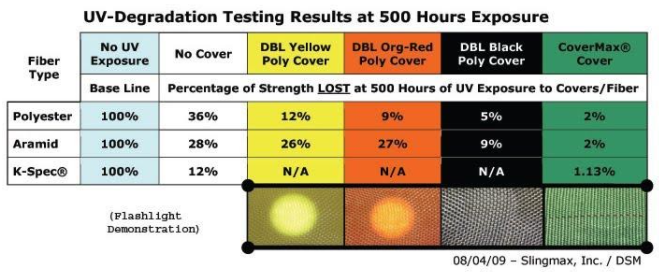

The best protection from UV damage of sling fiber is dark, thick, tight knit material. Round slings with light colored jackets can lose up to 40 percent of their ultimate strength over a six-month period. In the round sling color spectrum, white, tan, gray and yellow are the least protective covers, while red, dark brown, dark green and black are your best protectors against UV damage, according to the Rigging Institute. The more light that can shine through the sling’s protective cover, the more quickly UV damage is realized.

Gill said in the tower industry Dyneema slings are well adapted to severe heat conditions. “Their material has high strength, low stretch, and low creep but has a much more flexible rope/fiber,” she said. “It will not abrade itself like Kevlar and is now the preferred choice for use to replace wire slings and winch lines. The UV properties are excellent.”

Gill cited a study done by Slingmax™ (see chart above) and the degradation of UV where they tested the ropes in the sunlight for almost three weeks. Buckingham Mfg. Co™ attaches instructions and warnings with all of its harnesses for degradation of materials and wear.

She said Teufelberger™ also performed UV tests on various ropes and noticed an increase in elongation and stiffness in handling. When tested under loads, some of the ropes’ covers started to fray which implies fibers were damaged by UV and thus broke more frequently. Understanding UV exposure can cause yellow, stiffening, or a roughened coat and a strong decrease in the breaking load of ropes. Teufelberger™ researchers noted that polyester ropes are less susceptible to a reduction in the breaking load due to UV exposure.

“When UV exposure occurs on a rope, sling, or PPE, they must be taken out of service and not used again or used at home,” Gill said. “Understanding the materials used and the degradation due to weather elements can save a life and/or prevent dropped loads.”

Reader Interactions