The challenges around how drones can be used in the tower industry are “fundamentally not technical,” but “transitional,” as drone technology advances, 5×5 Technologies CTO Gary Gibson said during a NATE webinar Thursday. As part of the FAA’s National Drone Safety Awareness Week, NATE hosted the event, titled: “Drones, Data, and Artificial Intelligence.”

Drones can be used to collect data for various issues, including: re-climb inspection, height validation, antenna alignment, equipment validation/lease validation, mapping, structural analysis, pre-construction planning, mount mapping, tower health, and defects.

Remote sensing enables the operator to collect data such as equipment overheating or RF radiation patterns.

“Deep learning is driving the artificial intelligence revolution,” said Gibson. It’s possible to build more complex machines now with a higher computer power, which applies to AI and drones.

Concerning safe operation and navigation optimized for data acquisition, he said: “Today this requires a skilled drone pilot.” It may be desirable to operate a drone in bad weather or at night with the use of more sensors such as radar or lidar, according to Gibson.

AI can be used to help plan the path of a drone so it avoids obstacles. The level of autonomy will expand in phases over time, he believes. Eventually, “we’ll get to a point where we don’t need to pre-plan the flight path. AI will recognize” things like an antenna and know its density. “Today, all that needs to be programmed by hand,” Gibson explained.

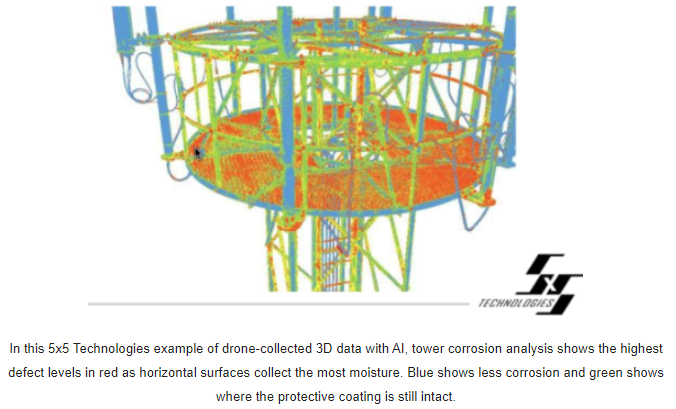

With two-dimension tower structural analysis, only the basics can be performed. 3D analytics can include jumper connection inspections, mount mapping or height validation. Surface analysis can detect rust and corrosion, and structural defect analysis could cover issues such as weld defects or cracks or bent members. 3D analytics can also detect missing fasteners, or damaged or improperly installed fasteners.

What does the future hold? Fully autonomous drone navigation and data collection can provide information for towercos “with no human intervention,” according to Gibson. A fully automated inspection means every part of a tower is identified, as are faults and anomalies. Automated structural analysis means 3D component models can be included as part of 2D and 3D CAD systems. That can mean simulating wind blowing over the tower to provide wind loading information required in the latest TIA spec, he said.

“We’re trying to get the industry into the SpaceX age where you have much more accuracy,” said Gibson. These futuristic drone capabilities, “will do a lot for tower safety.” He predicted with new AI-capable drones, “I don’t think [workers will] be climbing towers as much as they have in the past.”

By Leslie Stimson, Inside Towers Washington Bureau Chief

November 8, 2019

Reader Interactions