RF Industries, Ltd. is carving out a strong position in the telecom industry by offering cutting-edge solutions to optimize energy efficiency and operational performance, according to Pedro Yarahuan, Sales Director – Thermal Cooling Solutions, and Raymond Bibisi, President & Chief Operating Officer. The company’s Direct Air Cooling (DAC) ecosystems, developed by its division, Schroff Technologies International, Inc. (Schrofftech) aim to significantly reduce energy consumption at telecom sites, enhance existing HVAC equipment longevity, and significantly reduce operational costs.

A Next Generation of DAC Ecosystems

The DAC ecosystems from RF Industries have made substantial strides in offering sustainable and complementary benefits when co-existing with traditional HVAC systems. The core advantage of DAC, explained by Yarahuan, is its ability to reduce energy consumption by up to 80 percent and extend the life of the existing HVACs at the site.

“By utilizing fresh outside air in a controlled manner, the DAC system not only cuts energy usage but also decreases the strain on existing HVAC systems, allowing them to last longer and need less maintenance,” he said. This helps companies save on electricity and reduce repair and replacement costs for HVAC systems as well as significantly reducing the number of site visits.

That said, it doesn’t need to replace HVAC systems entirely. Bibisi emphasized that the system is complementary to HVAC systems. “The DAC system works in tandem with HVAC units, coexisting to deliver improved thermal efficiency,” he explained. The versatility of DAC allows it to be used in different settings, such as small telecom shelters, cabinets and other enclosures, making it highly adaptable to various telecom environments.

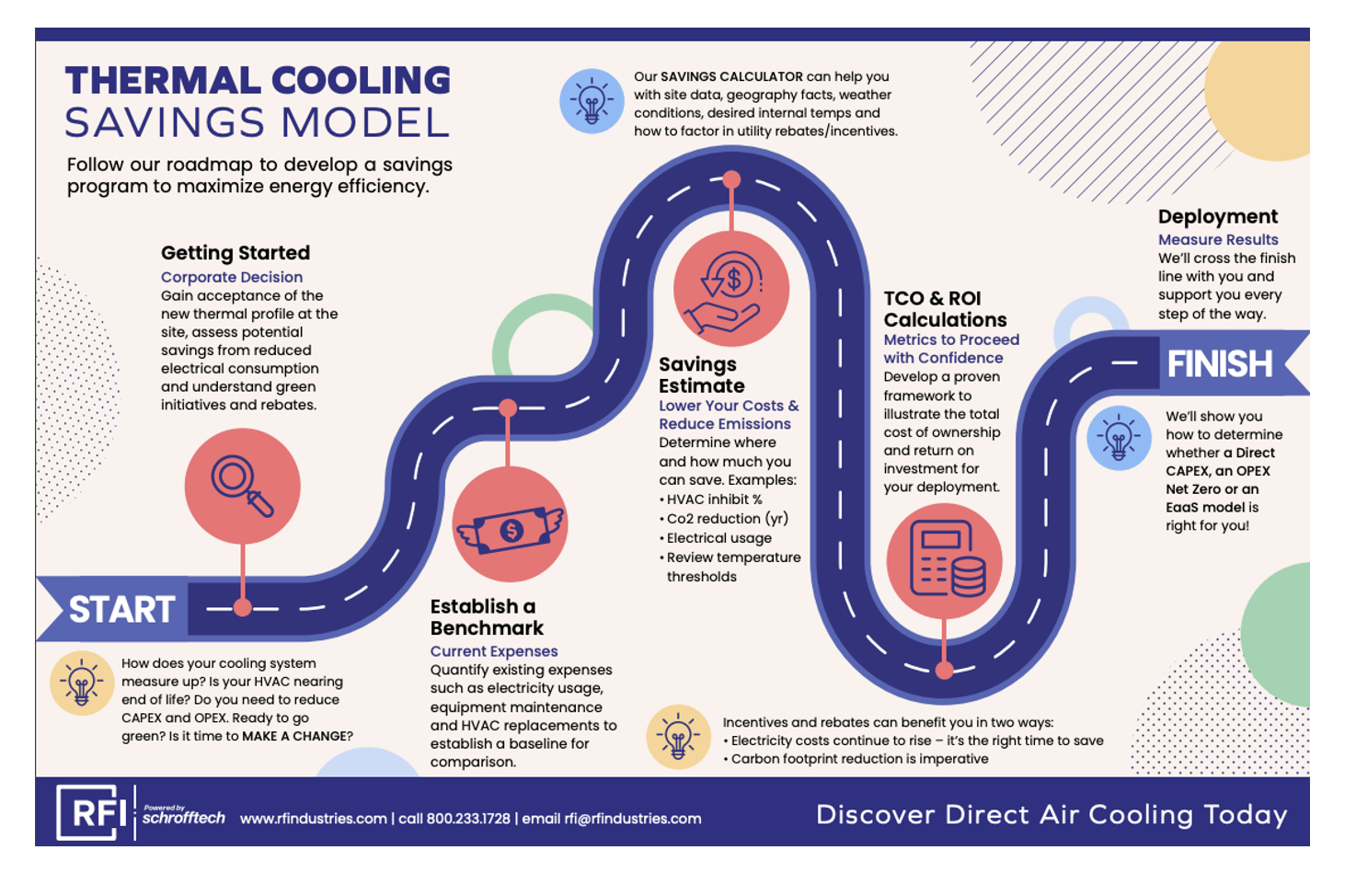

The RFI Thermal Cooling Savings Model

Yarahuan explained how the company collaborates closely with clients to adopt a new philosophy operating their network using direct ambient air, gathering data on current utility bills, maintenance costs, and HVAC replacements. “We establish a baseline of expenses collaboratively, up until the team believes that the data is accurate, then, through evolved and tested savings calculators, we collaboratively estimate how much can be saved by implementing the DAC system,” Yarahuan noted.

This data-driven approach has been key to proving the savings model value. By calculating the expected savings in energy consumption and extended HVAC lifespan, RF Industries can show customers a clear path to return on investment (ROI). In a recent project for a major carrier, the company demonstrated that within 4.9 years, incorporating DAC systems would offset the client’s 10-year TCO (Total Cost of Ownership) investment and operating cost for the system, allowing for 5 years of undiluted return of investment (ROI), translating in significant financial gains in the years ahead.

According to Bibisi, the initial development of project frameworks (CAPEX, Net Zero (0) OPEX, EaaS, etc.) takes time due to the complexity and the need for precision. “It took us about 1.5 years to finalize the details for a large-scale project because the client wanted to explore every alternative. But now that we’ve completed this validation and we have experience and partners for each framework, we’re more prepared for future projects,” he said. The attention to detail ensures customers have confidence in the savings projections.

Advanced Control Systems for Simple Integration

One of the most significant advancements in the RFI DAC ecosystems, according to Yarahuan and Bibisi, is its new control technology. Next-generation controllers are highly automated, allowing for wireless site monitoring and integration with existing systems. The controllers connect the entire ecosystem of HVACs, DAC systems, and generators, and associated sensing capabilities providing a comprehensive view of energy consumption and operational performance. “We can now enable access to the ecosystem from a phone or tablet using WiFi, remotely monitor the system via SNMP traps, track the energy consumption status of the entire site via IoT with our NextGen Sensors, and access and retrieve historical data for performance analysis,” Yarahuan added.

The RFI solutions ensure the site remains operational during power outages and counts with the M/V (Measure and Verification) technology that allows customers to track energy savings and claim carbon tax credits under Section 45Q of the IRS code, boosting the financial incentives for adopting DAC technology.

In some states, utility companies offer rebates and/or cash incentives when using DAC technology, which provides additional incentives to offset project costs and accelerate ROI.

The Roadmap for DAC Deployment

RF Industries’ recent $2.7 million order from a major carrier has corroborated the company’s long-term roadmap for DAC deployment. According to Yarahuan, this project has cemented the DAC system’s reputation as a viable, cost-saving technology that aligns with the green initiatives of tier-one telecom operators. “Our model has been validated, and we’re ready to take on more projects,” he affirmed.

According to Bibisi, RF Industries isn’t just a cable and connector company anymore. “We’re a company of innovation, offering future technology solutions,” he said, highlighting the company’s evolving role in the telecom industry. As RF Industries continues to push boundaries with its DAC system, Yarahuan and Bibisi agreed, the company is well-positioned to become a force in energy-efficient telecom solutions.

To learn more, visit https://rfindustries.com/thermal-cooling-solutions/.

Reader Interactions