Deploy

Introducing their first version in 2014, Drake Lighting’s V1 High Intensity Obstruction Lighting system for broadcast towers is the only solution that has the power, controls, and monitoring on the ground. The system requires only the LED lights at height which provides easier installs and fewer, if any, tower climbs for maintenance.

The solution, which has since been upgraded and named V2, features three lights at each level and two runs of 12-gauge wire down the tower to the distribution box. “Simplicity is the number one advantage with the V2, especially for those working on these towers up to 2000 feet,” said Mark Walker, Broadcast Sales Manager, Drake Lighting. “It makes it a lot easier for them to install our system.”

Locating the power supply and control mechanisms at ground level also keeps the repairs to a minimum, because the electronics are not out in the elements. “You won’t need a tower crew every time a light goes off; more than likely the problem is going to have something to do with the electronics,” Walker said. “With the electronics inside the transmitter building, the site engineer or site manager can quickly change something themselves. It’s very cost efficient.”

Each tier of lights has its own power supply unit, which converts the power to DC, in a 19-inch rack inside the transmitter building.

The rack system that houses the ground-based equipment. The front of the unit is on the left and the back is on the right.

Some of the V2 systems have been in the field for five years now and Walker says there have been very few alarms or replacements of equipment needed for the systems. Another cost saver, the V2 does not require thousands of feet of communications line going up and down the tower to monitor the lights. Instead, the current going up to the lights is monitored.

There are four systems with the V2 solution to meet different FAA requirements. The specifications of each of these options can be found here.

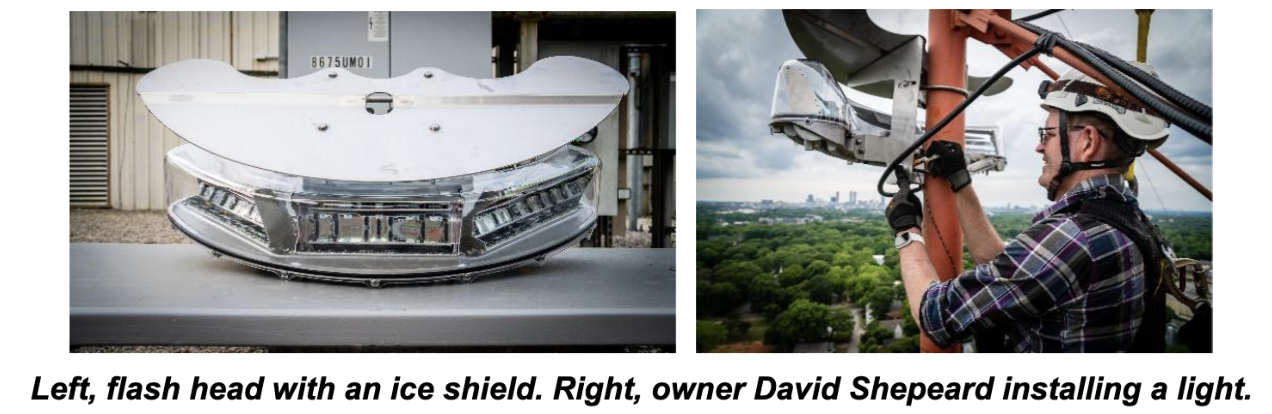

Along with easy installation, the High Intensity Lighting System offers tower technicians much lower weight per tier, which is about 100 pounds, compared to 500 pounds for other systems. Along with lower installation and maintenance costs, Drake’s High Intensity Lighting System provides broadcasters lower wind loading. Other features include premium monitoring, a five-year parts warranty, optical design to reduce ground disturbance, and simple lightweight mounting connection to towers.

For more information, please visit here or contact Walker by email: [email protected] or phone: (270) 978-8349.

By J. Sharpe Smith, Inside Towers Technology Editor

Reader Interactions