Since the mid-1990s, the City of Los Angeles has recognized that citywide coverage of wireless service is an important element to support smart city services. The city considers streetlights to be the best location for new wireless sites since they are at the optimum height, have existing electrical infrastructure, and do not add an additional structure into the public right of way. The city proactively works with carriers to attach small cells to existing streetlight poles to eliminate additional unsightly poles and cabinets installed in already busy sidewalks.

To facilitate new services, such as 5G Fixed Wireless Access (FWA) and mobile applications, the LA Bureau of Street Lighting (BSL) has established policies, specifications and procedures for co-location of cellular sites on streetlight poles. Working with a tier-one carrier customer, Raycap engineered a small cell streetlight design, based on LA BSL specifications, that provides a path to widespread installation of small cells in Los Angeles and possibly even provide a blueprint for neighboring cities.

The delicate balance of 5G functionality and aesthetics

The LA BSL is responsible for the design, construction, operation, maintenance and repair of more than 210,000 lights throughout Los Angeles, consisting of more than 400 designs. BSL regulations provide a framework for integrating wireless services with its more modern streetlights, striking a “delicate balance” to meet the demand for 5G mmWave small cell sites and evolve the aesthetics of the attachments.

Raycap recently received approval for a streetlight pole design that integrates 5G small cells and meets the specifications from LA BSL. These poles will replace existing streetlights, so they needed to conform to a very specific form factor. The pole itself is 12 inches in diameter and all the wireless small cell electronics, plus as much wiring as possible, must fit within the pole to maintain aesthetics. The pole design needed to work at three designated heights: 31, 33 and 35 feet, with BSL-approved locations for luminaires attached on the pole.

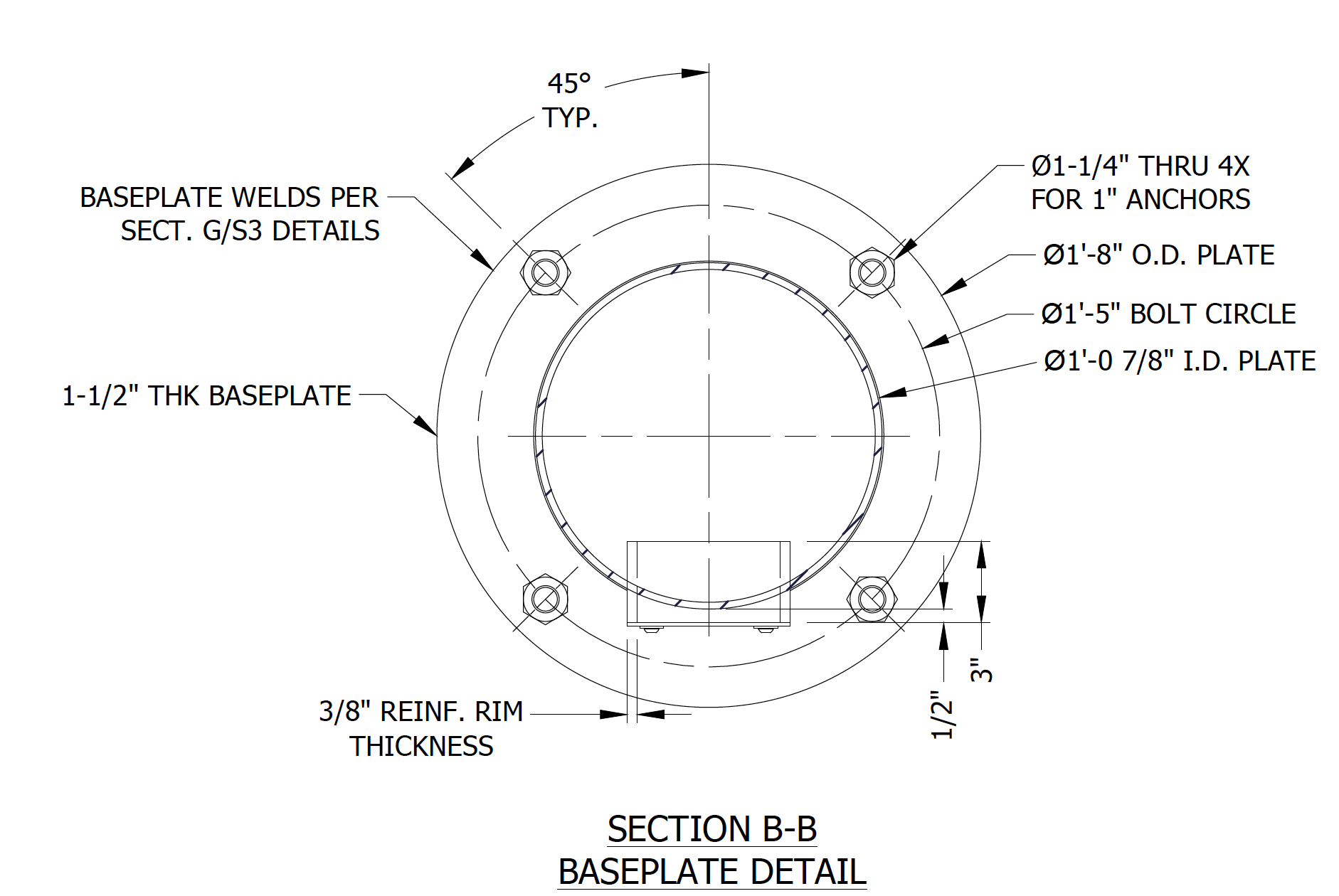

At the base, the integrated pole had to be 100% compatible with other common streetlight poles. For example, it needed to match existing bolt diameters and patterns per BSL established foundation standards. This simplifies replacement of existing poles by avoiding rework of the foundation. In addition, the LA BSL wanted to be sure that, in the future, if the site is no longer needed for telecom services, the city can easily remove the pole and replace it with a normal streetlight.

The design, dimensions and thickness of the 12-inch pole have been verified to meet LA BSL structural specifications by a registered professional engineer in the state of CA. While this design was executed for a specific tier-one carrier in that area, Raycap anticipates that the design is flexible enough to support the needs of other carriers as well.

The challenges of 5G streetlight integration

While meeting the dimensional specifications for the integrated streetlight pole required significant precision, Raycap’s engineers also had other challenges to overcome to make the design effective for 5G small cell sites.

Accommodating radios from multiple manufacturers – Raycap engineers tackled the challenge of integrating the radios, support electronics, power and fiber management and the ventilation system in the interior of the 12-inch pole pipe. Because the carrier customer had not specified an individual manufacturer’s radios at that time, Raycap depended on its extensive experience with 5G radio electronics, and in designing its own integrated small cell pole product. They interacted quite frequently with LA BSL to solve all the mechanical challenges and to provide confidence that future 5G radio equipment would operate correctly once installed inside the pole.

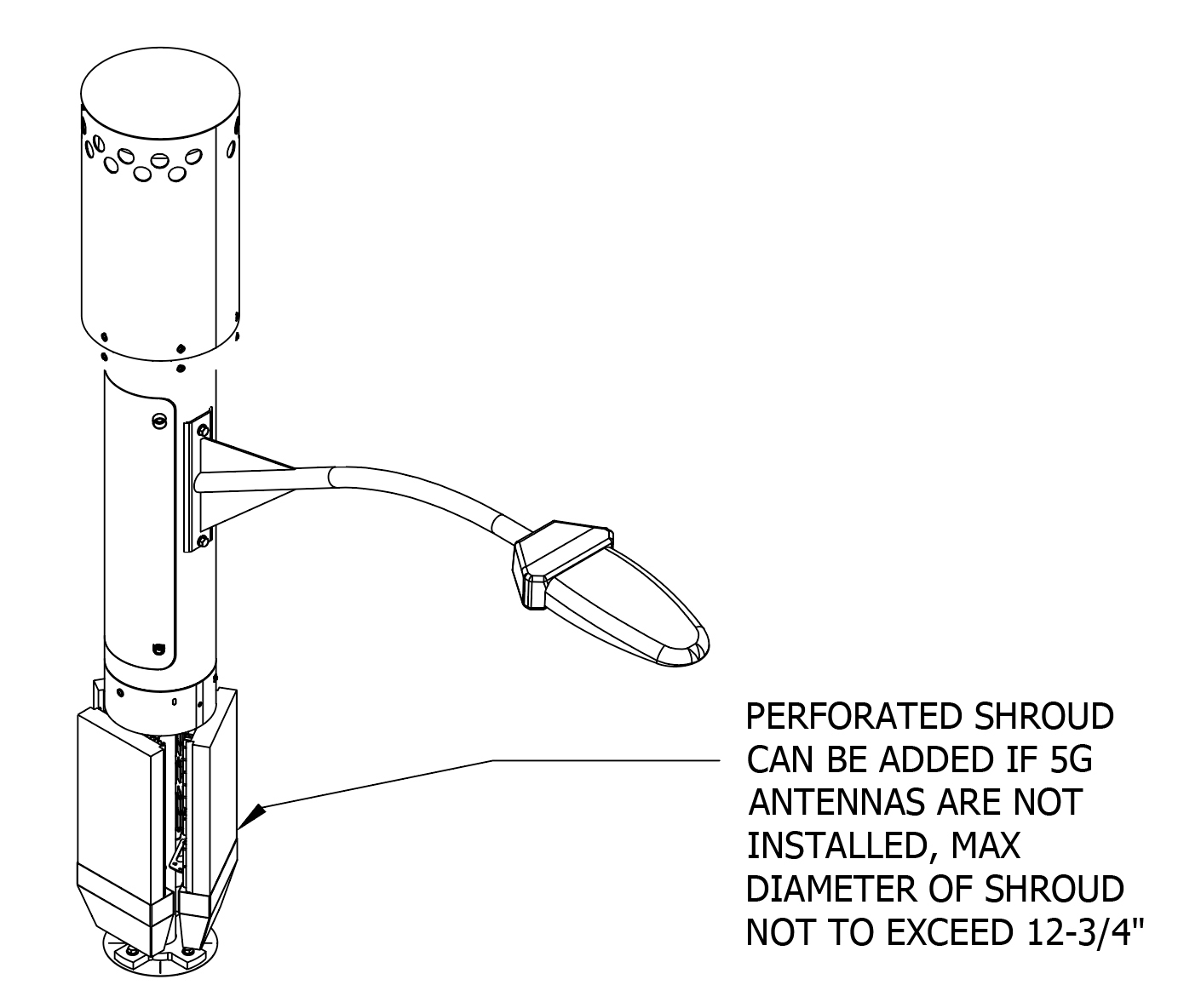

Flexible space for 5G antennas – Likewise, the design had to account for future 5G antennas. Working with LA BSL, Raycap engineers designed a section for 5G antennas below the mounts for the luminaire arms. The section is large and flexible enough to accommodate a range of expected 5G antenna products. If 5G antennas are not ready or not planned for a particular site, carriers can install preformatted shrouds over that section of the pole.

Conceal all support electronics – In addition to hosting radios and antennas, small cell sites have a number of support systems that must be integrated. Raycap engineered all of these systems out of sight, within the pole: power metering and management, AC disconnect with surge protection, fiber management and air ventilation systems. The engineers performed sophisticated thermal analysis of the assembly to ensure it would operate as expected during LA’s hot summer days. The design also specifies cable management, to limit any need for external cabling.

To access the equipment inside for installation, maintenance and future upgrades, Raycap added three doors to the design. To help prevent unauthorized access, all doors are at least 10 feet above ground level and have quarter-turn cam locks with optional padlock attachments.

Ramping up for manufacturing and installation

Next, Raycap manufactured a prototype of this pole design and delivered it for BSL inspection in January of 2020. Passing inspection, the pole was installed in February. The electronics and radios from the carrier were delayed by the pandemic and were not installed at that time. LA BSL approved the shop drawings for the pole (number RAYCAP RCP-BSL2) on March 27, 2020.

After Raycap completed the trial, the process continued: a materials control inspector from the LA Bureau of Contract Administration scheduled a shop inspection to complete certification. A few weeks later, a representative came to Raycap’s South Carolina manufacturing facility (one of three domestic U.S. factories) to assess its production capabilities and process. As a result, LA BSL has announced that Raycap is now an Approved Fabricator for small cell streetlight poles across the city.

Raycap is ready to deliver the small cell pole to customers and partners in the LA area. Since this is a fully engineered design, the company is prepared to ramp up to mass production within three to four weeks of orders. To meet installation schedules, Raycap can even arrange for weekend shipments. If carriers want an even faster deployment process, Raycap can pre-install, pre-integrate and pre-test radios and electronics at the factory, so that the products can be sent ready to be installed. Wireless technologies will evolve rapidly for the foreseeable feature as 5G technologies mature, so the ability to easily update the radios after installation is a critical capability.

Reader Interactions