The term “digital transformation” has been around for about 30 years, and for good reason. Each digital transformation has led to the next. The latest transformation leverages artificial intelligence to turn hi-res photos taken by drones into exacting digital replicas, known as digital twins, and automatically deliver engineering grade measurement data in actionable report formats and input for structural analysis software.

“Accurate data is needed to properly and efficiently manage disparate or distant infrastructure assets,” Pat Lien, Pointivo Vice President of Sales and Marketing, told Inside Towers. “The collection of data has advanced dramatically with the use of drone imagery as inputs to create highly accurate analytics. They are really the key to creating efficiency and proactive management of assets.”

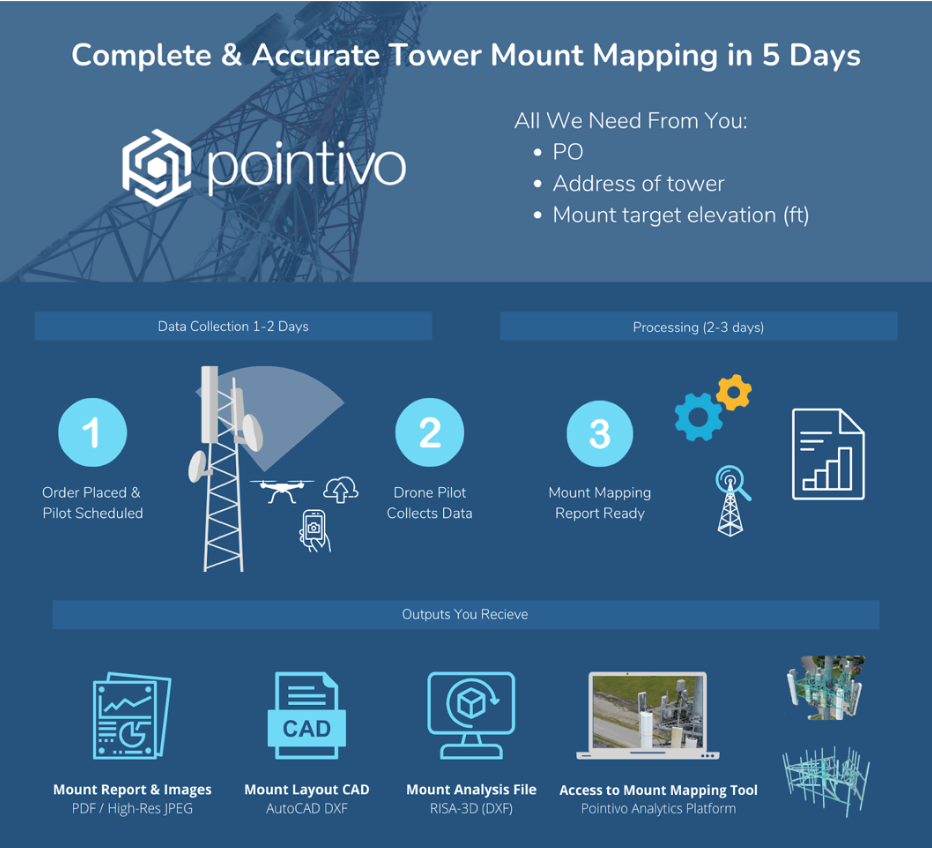

With the shortage of tower climbers, using drones to map antenna mounts in advance of antenna installs and modifications has been a priority, according to Lien. Automating antenna mount mapping, site audits, contract compliance, tower mapping and inspections is critical, but Pointivo also delivers complete and actionable reports which can be easily uploaded into other engineering analysis programs. Engineers can dramatically increase their workflow and avoid lengthy review and data transfer tasks, prioritizing their time on analysis and design.

“We thought, if we can collect the data very efficiently on mounts, and apply our AI driven analytics, we can deliver precisely the same, or perhaps an even better, end product to engineers and tower owners,” Lien said.

To begin the process, Pointivo dispatches a professional drone pilot, who uses an automated flight application to collect the tower mount images and uploads them to the analytics platform, transforming them into precise measurements.

In the second phase, the measurement and identification of every element of the mount is executed using artificial intelligence and computer vision in the Pointivo platform, which has access to 6,000 catalog elements from all of the major manufacturers.

The third phase involves precisely mapping the known dimension elements of the mount to what is seen in the imagery.

“This is not a calibration to two or three millimeters. It’s a precise match of every mount element, antenna, and remote radio unit, according to the specs and the dimensions in the imagery,” Lien said. “Structural engineers need to understand the mount configuration, because that has a very substantial impact on the loading, but they also need to have accurate detail on the type and thickness of the members themselves,” Lien explained. “They need to know the size of everything from the attachment plate to the tie back rods, angle iron, and the mount pipes. Each of those elements has to be accurately measured and identified in order for there to be the most accurate mount analysis.”

Mount analysis software applies the current standards of wind loading for the antennas, as well as the weight, and looks for the weakest point or the point of first failure to make sure the capacity of that mount is not exceeded. The mount analysis process relies on complete and accurate mapping data.

“The automation algorithms that we’ve created tell the computer what to look at and how to classify it, once the dimensions of each of the elements have been accurately determined,” Lien said. “It centers around the accuracy of the model data, our ability to precisely identify each element and confirm dimensions, and, third, the platform automation that allows us to do this in just a few hours.” The demand for accurate, timely and efficient technological processes to expedite crucial network rollouts and enhancements confirm that legacy approaches are not sustainable.

Digital transformation will continue to improve with AI, sophisticated analytics and automation. Pointivo’s software learns with every mount mapping that it performs. The company also provides drone inspection analytics for facility assessment, residential solar, and energy infrastructure. Each of those verticals share techniques developed for the Pointivo telecom analytics platform.

“Having evaluated over 35,000 towers and 120,000 structures last year, we have an enormous amount of data for artificial intelligence to continually improve,” Lien said. “Everything that is learned in one industry — techniques and elements — is applied across the entire platform.”

For more information about Pointivo and cell tower drone inspections, please visit here.

Reader Interactions