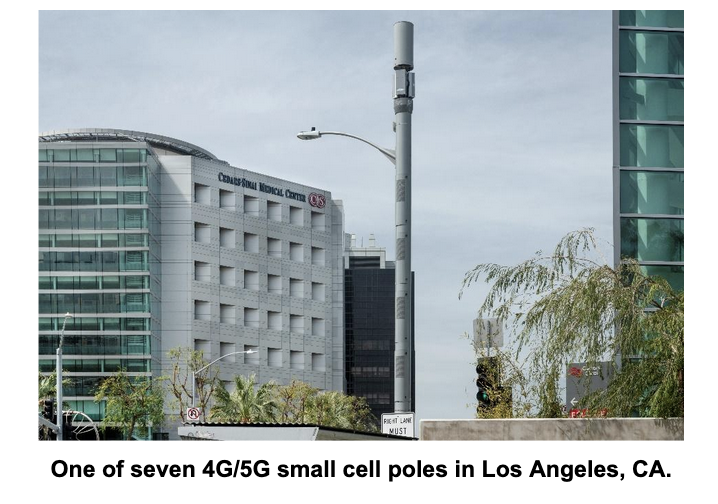

The concealment business has been in expansion mode the last few years, and the recent auctions for the C band spectrum will drive even more momentum. Now that the carriers have spent billions for these frequencies, it’s time to deploy the network, which increases demand for small cells with concealment. That will be anything but slow, Apostolis Sotiriou, Vice President, Sales at Raycap, told Inside Towers.

“C band will first cover suburban environments,” Sotiriou said. “I wouldn’t say that we will see a site build explosion in 2023, including small cells, but I would say, based on what we are hearing, that there’s going to be a constant increase.”

Raycap is getting ready for that demand. “It is a very slow process for the carriers to get the approvals. Once that happens, everything moves quickly and everybody wants to have products, not in a few months, but in a few weeks,” Sotiriou said.

Increasing speed has meant, for Raycap, a focus on enlarging the capacity of its east coast locations. In North Charleston, SC, Raycap manufactures structural steel products, like small cell poles and mounts, as well as composite products like InvisiWave toppers and screen walls, and macro site concealments of all kinds.

Adding to its nearly 200,000 square feet of operations already in North Charleston, a building with 40,000 square feet has been brought online to accommodate additional equipment assembly and warehousing. The company will hire 50 employees to speed up the assembly process and is currently expanding its machinery to include more bending, punching, and laser cutting machines.

“We’re looking forward to the additional capacity to take care of our customers, to get products out the door more quickly, and to be able to take on new product lines as they’re developed,” said Trey Nemeth, Senior Vice President, North American Operations, Raycap.

Raycap is also ramping up operations in their Kearny, NJ facility, where it forms the metal for all the parts for small cell concealment solutions, as well as designs and assembles equipment shrouds, cabinets, and other enclosures. Throughput will be doubled by adding equipment, doubling space, and increasing employment by 25 percent. The expansion is part of Raycap’s plan to produce products in the U.S. that are currently manufactured in its facilities in Europe.

North Charleston will also be the home of new automated powder coating equipment. “We will be manufacturing sheet metal parts in both of our east coast facilities and then powder coating in Charleston, to support the new Charleston assembly facility as well as our existing assembly facility on the west coast,” Nemeth said.

By expanding the facilities on the East Coast and increasing capacity, Raycap will reduce backlog, and reduce lead times. It will have the ability to assemble products in the geographic area closer to where they will be deployed, thereby reducing shipping time.

“Each facility has its own core competency,” Nemeth said. “But when it comes to the assembly specifically, we’re able to pick and choose the facility in which we’re going to perform the work based on a variety of factors, sometimes including geography.”

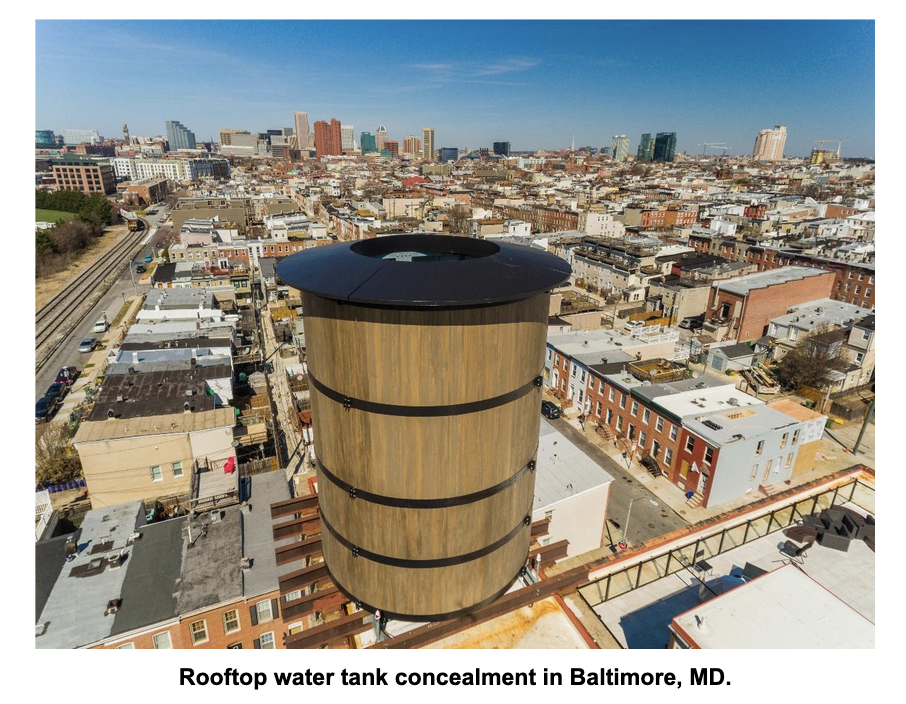

Manufacturing is not the only thing that must be fast, Sotiriou noted. Every city has different needs when it comes to small cells, and within each city, every carrier may have three or four different projects, each with different aesthetic requirements.

“We have realized that we need to be very fast in drawing and designing a pole or a concealment solution,” he said. “And quickly convert a drawing into something that can be manufactured in order to move ahead with a proposal simulation for the carrier to approve.”

Adding technology to speed manufacturing will only take Raycap so far, though. Successful concealment depends on the creativity of individuals. “We need to have innovative ideas about how to address the municipality requirements,” Sotiriou said. “And then we need to have a strong design engineering team to turn those ideas into solutions for our customers.”

For more information about Raycap, please visit: https://www.raycap.com/.

By J. Sharpe Smith, Inside Towers Technology Editor

Reader Interactions