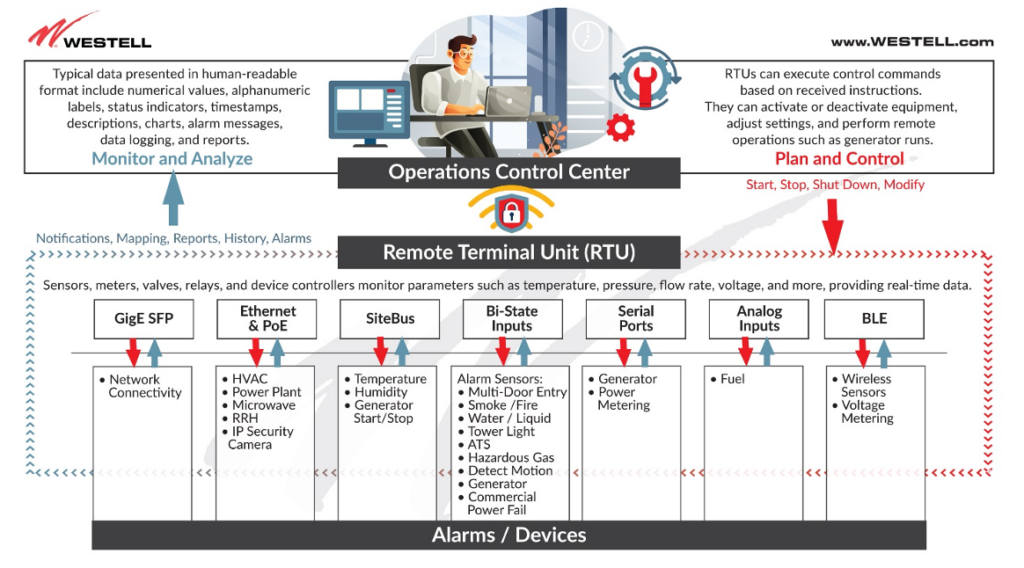

A Remote Terminal Unit (RTU) is an important component in monitoring and controlling devices at telecom sites. These microprocessor-based electronic devices capture the digital and analog parameters of any number of metrics — tower lights, security of the compound, generator status, fuel levels, environmental alarms, temperature, and exact power usage per tenant. They then transmit the data to a master station for the user to review or take action.

An RTU must connect to several different types of edge devices in the field, in a variety of ways. It also has to speak the different “languages” of each device, so it can provide the tower owner or carrier valuable information, Amy Walther, VP of Sales and Business Development-ISM Monitoring at Westell Technologies, Inc., explained to Inside Towers.

“The different types of ports in an RTU serve different purposes,” Walther said. “It’s important to have the ability to connect to a variety of devices, even analog and serial. Devices still exist that connect with a serial port, and there are different types of serial ports, including RS-232 or RS-485.”

RTUs are the best option for monitoring and controlling devices in this IoT world, according to Walther. The only other alternative is logging into devices in the field remotely through a router, which can be reached through an ethernet connection. For this type of connection to work, an employee must manually log in to each device individually using its specific IP address to extract the information as frequently as the data needs to be tracked. This could be daily, or even more often, if there is an issue at the site.

“If someone only had a few things to connect to every day, maybe that would work for them, but usually when you have many sites — let’s say 10 — it’s just too much for any person to keep logging into all those devices,” said Walther. “Additionally, some companies do not allow devices in the field to be logged into on their network, because of security concerns.”

When companies use an RTU, they benefit from its secure connection, which keeps the user’s network from being hacked. “That is one of the things that people need to think about when they’re looking at protecting their network and ensuring everything is safe and secure,” Walther said.

RTUs come in different shapes and sizes, which allows for the flexibility of mounting them in racks, NEMA enclosures, DIN rails, and backboards. The different shapes and sizes of RTUs also offers the customer budgetary options.

“It’s important to find the right fit for the customer, because you don’t want to put someone in an RTU that has zero room for growth. We know all of our networks are going to grow,” Walther said. “It is good to know that if expansion is needed in the future, the capability exists.”

Tower Site Monitoring

RTUs are critical to operating tower sites with multiple management functions, whether it is billing for power usage, starting and stopping the generator using an automatic transfer switch, checking fuel levels, or monitoring dry (door) contacts.

“It might seem like they are old school, but we always monitor a number of dry contacts with each one of our RTUs. Customers want to know when their doors are opened,” Walther said.

Natural disasters are a big driver for the deployment of tower site monitoring, according to Walther. They expose the importance of increasing the visibility of the tower operations. She points out Superstorm Sandy spurred a lot of that interest. In 2012, the storm caused $68 billion in damage on the Atlantic Coast.

“This event triggered companies to do something about monitoring their tower sites. Not only did it knock out power, but it lasted for a long time, and generators began to run out of fuel, and then batteries died — one at a time,” she said. “Nobody knew when each generator would run out of fuel next, or when their batteries were about to die. It was chaotic.”

More than ten years later, communities are even more reliant on cell phone service, as opposed to landlines, for calls including 911 service. “The reason why it is so important to monitor cell towers is because the primary way you’re getting a 911 call out nowadays is a cell phone. These cell sites have to remain operational,” Walther said. “And it’s very important for the technicians who are monitoring the networks to know whether a site is working or not.”

There are a number of other requirements that have driven companies to increase their monitoring capabilities. Walther cites a greater need for security in the tower compound as an example. She also notes that technicians are responsible for more towers today over a wider area.

Some states require companies to file the odometer readings on all generators. With an RTU, the generator’s odometer can be read remotely without having to physically send a worker to the tower site. The amount of fuel delivered to the generator can also be remotely monitored to make sure there is no theft.

Tower sites can be difficult to reach. It may take a snowcat or a helicopter to get a tower technician to some sites. It is common sense to have remote monitoring and control at those sites, says Walther. But what about the sites that are a four, five or six hour drive away? Remotely monitoring and controlling these sites will reduce OpEx with a reduction in the number of truck rolls and in technicians’ hours behind the wheel for all sites, she explains.

Westell provides wireless sensors that connect to devices in the industrial space, eliminating the cost to wire up to the RTUs. This helps with monitoring units in indoor, as well as outdoor spaces. “We have added wireless sensor support, using 900 MHz frequencies, to provide a strong signal that can go through walls,” Walther said. “Any kind of sensors like a temperature, vibration, or a fuel sensor, we can connect to them.”

Without a wireless sensor, to monitor the fuel in a propane tank, a trench must be dug to wire the generator to the propane tank, which is expensive and requires a safe barrier. “When we use a wireless fuel gauge, we don’t have to do any of those things. It’s less expensive and safer, too,” Walther said.

For more information, download the white paper: “Understanding the Role of a RTU in Intelligent Site Management”. You can also contact Westell about their RTU solutions.

By J. Sharpe Smith, Inside Towers Technology Editor

Reader Interactions