The engineered steel structures designed and manufactured by Ambor Structures are not limited by borders or by the imagination. Begun in 2014 in Minnesota, with production in Shanghai, China, Ambor supplies steel poles for the telecom, small wind, utility, and lighting verticals. The steel structures go around the world, including the Europe, North America, the Caribbean, Australia, Japan, and China.

“It was our desire to tap into new and varied markets. Manufacturing in Shanghai allows us to maintain similar pricing and shipping costs in each country,” said Andrew Murray, Sales Director, Ambor Structures.

With the main target in North America being telecommunications, Ambor entered the U.S. to provide a low-cost, high-quality product, which was manufactured to the same standard as any other U.S. product using American-grade steel, according to Murray. All of the welders are AWS certified and the facilities are ISO certified. “The combination of high-quality and low-price has been a game changer for us,” he added.

Ambor has grown its team in both China and in the U.S. to better support its growing business. The manufacturer began with an 80,000 square foot factory in Shanghai, and, in 2020, acquired an additional 200,000-square-foot factory in the Qingdao port of Shandong, China.

“We’ve just expanded and grown our capacity so that we’re able to better support the needs of each market,” Murray said. “That growth, the diversification and our staff growth have allowed us to penetrate any market relatively quickly.”

What Ambor Provides

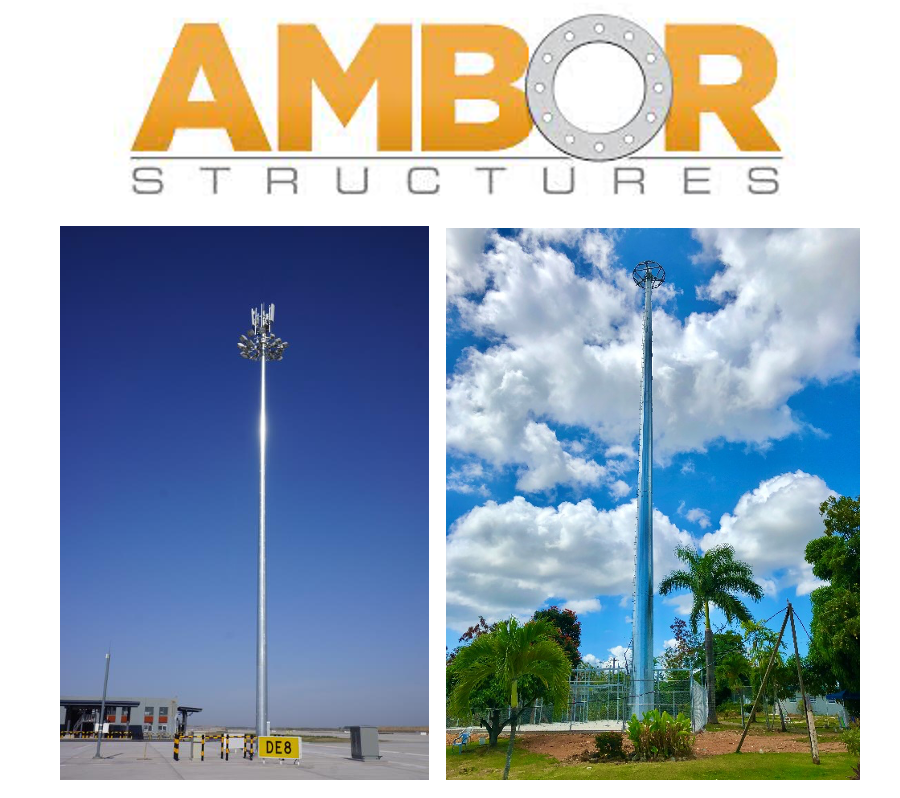

Ambor provides the telecom industry with new build standalone monopoles. It also provides concealed structures, typically in partnership with several other companies in the U.S., via RF transparent fiberglass or tree concealments. It offers small cell 5G pole structures as well.

Along with manufacturing towers, Ambor offers a non-penetrating, concrete-free foundation solution, known as QuikBase, for sites in remote areas. For installations with time constraints, it can be assembled in as little as 1.5 hours by a two-person crew.

Additionally, Ambor supplies telecom components for mounting antennas, including multi-sector ring mounts, low-profile platforms, standoff arm kits, T-arm kits, ice bridges, and roof mounts. Its pole raising systems give a construction company the ability to quickly raise and lower a monopole, which eliminates the need for a crane, and saves time and money on installation as well as maintenance. Their Quikbase foundations allow for a non-penetrating solution for poles to be erected for short term projects, or areas where ground disturbance is not allowed.

Ambor doesn’t just manufacture poles. It also offers engineering services, designing structures that offer solutions to meet the aesthetic prerequisites of the jurisdictions they serve for new antenna technology and concealment.

“We try to stay ahead of the curve and offer engineering services at no cost to our customers to either economize the structure to save money, or to better suit what their structure needs in terms of new technology,” Murray said. “We want to help drive solutions on the ground floor of designing the pole and utilization of the product.”

Customers approach Ambor with information on the antennas that tenants plan to mount on the pole. Ambor then designs the structure according to the needed mounts and anticipated loading, as well as future loading from additional tenants.

“It’s always a collaborative effort. Design codes vary by jurisdiction, which changes wind and ice loading. We move and adjust those changes,” Murray said. “But I think the biggest thing is to support customers when they are in areas where it is challenging to get a permit.”

Enter the Mini-Macro

Sometimes less is more, and Ambor has been following the trend to build smaller macro towers, known as mini-macros, that still have enough capacity for the antennas to meet market needs for data usage.

“There is a significant need to build mini-macro sites, because tower developers are trying to build macros and just hitting brick walls,” Murray said. “We’re not trying to put 150-foot or a 200-foot monopole in a suburban area. We are trying to put an 80-foot or 100-foot engineered structure that is designed to blend in and look like existing infrastructure.”

For C-band deployments, Ambor has been building more mini-macro structures, refining the antennas that are included in those structures, so they can be concealed. It works with several tower concealment firms to find the right camouflage.

“I think that we’ll start to see more and more requests for mini-macros, because the demand is in the suburban areas where our data consumption just continues to increase,” Murray said. “Coming up with more appealing and creative ideas for telecom structures is going to be the future of our industry.”

Conclusion

By staying in close touch with tower site developers, Ambor is able to stay on top of the wireless infrastructure market. Whether it is small cells, mini or macro cells, or rooftop installations, it says it will help drive the engineered steel solutions that meet their needs in the future.

Ambor will be exhibiting at booth 809 at Connect(X) May 8 – 10 in New Orleans. Be sure to stop by and visit them.

For more information, email Murray at [email protected].

Reader Interactions