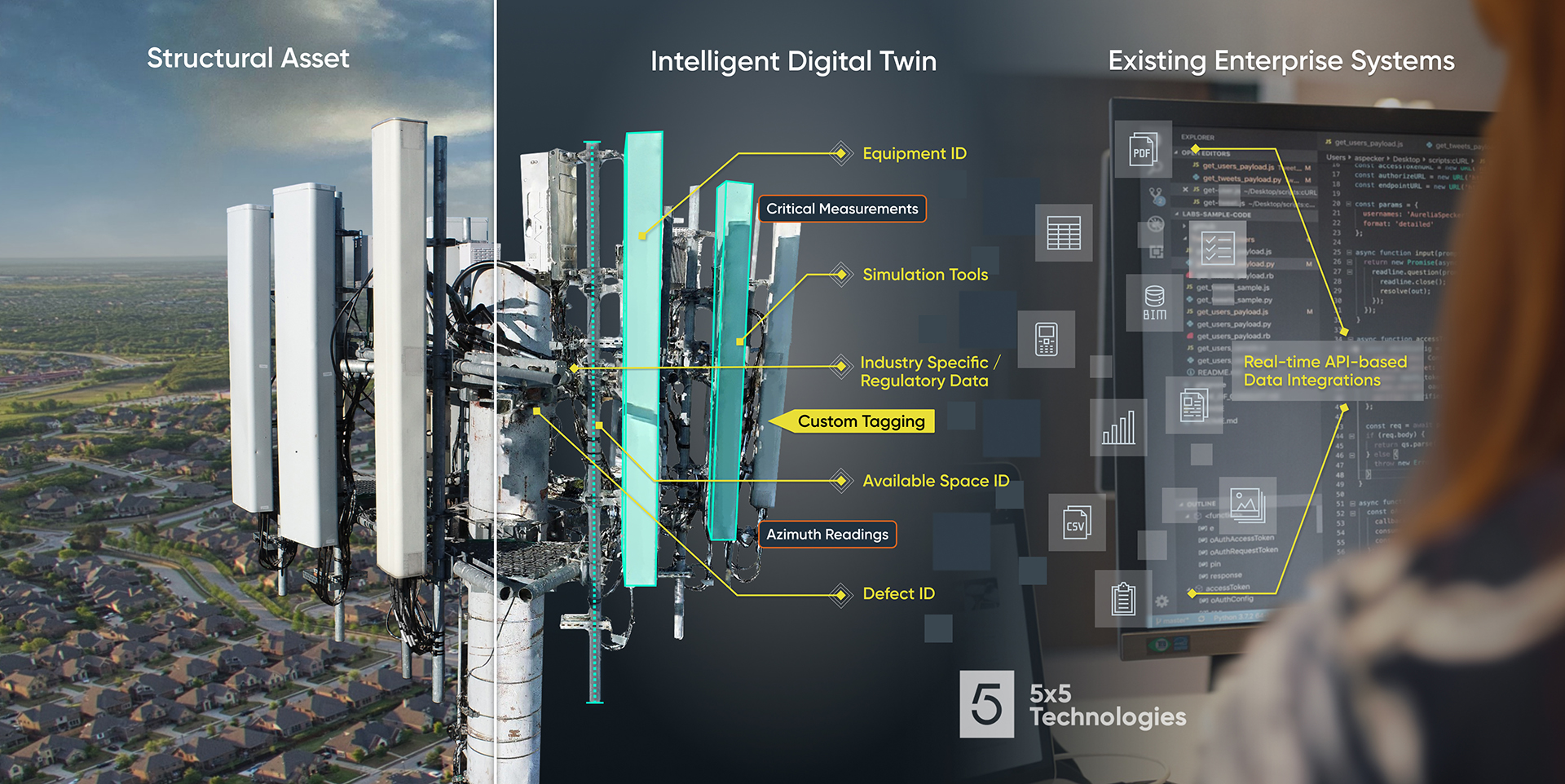

Having an exact digital replica of an existing structure, or digital twin, can give a carrier or tower company a window into all the equipment attached to that steel, a magnifying glass on any spots of rust and a clear vision of how much space is available to lease. 5×5 Technologies delivers a digital twin platform which allows companies to see what’s on the tower and optimize the value of that asset.

Having an exact digital replica of an existing structure, or digital twin, can give a carrier or tower company a window into all the equipment attached to that steel, a magnifying glass on any spots of rust and a clear vision of how much space is available to lease. 5×5 Technologies delivers a digital twin platform which allows companies to see what’s on the tower and optimize the value of that asset.

“What we’re really doing is helping a telecommunications company power a digital transformation that allows them to reduce costs and improve revenue for their assets with a major focus on cell towers and telecommunications infrastructure,” Scott Carr, Head of Product at 5×5 Technologies, told Inside Towers.

The concept of digital twin technology dates back to the early 1970s when NASA was building big rockets to go to the moon, according to Emerging Tech Brew, and it started becoming a reality with the rise of the Internet of Things around 2010. Recently, the rise in digital twin usage has been made possible by advancements in artificial intelligence and the increasing adoption of digital transformation, according to Information Age.

Today, digital twins are estimated to be a $3.1 billion market with the prospects of growing to $48.2 billion by 2026, according to Markets and Markets, with penetration into nearly every vertical, including telecommunications, healthcare, retail, logistics and equipment maintenance.

“For enterprises, digital twin technology not only provides the opportunity to grow and optimize but also a way to improve strategies and business processes,” according to Forbes. “More importantly, this technology seeks to fulfill a promise to put enterprises one step ahead of the competition.” A recent article in VentureBeat said digital twin technology is a leading trend in enterprise strategy. “These digital copies are increasingly popular because they can be used to drive important simulations that haven’t been possible until now,” VentureBeat wrote.

5×5 Technologies’ team of computer scientists, mathematicians and PhDs has developed patented methods of structural asset management known as 4D+AI. This approach is designed to make digital twins more intelligent and useful to client companies. It starts by modeling tower data in three dimensions and over time (the fourth dimension) adding multiple layers of information. As a result, analytics, equipment ID, change detection and other measures can be automated.

Using artificial intelligence, 5×5 Technologies enhances what would otherwise just be a 3D model with metadata, according to Chris Fawcett, Chief Marketing Officer, 5X5 Technologies.

“This opens up opportunities for personnel in sales, operations, maintenance, construction and the CIO’s shop,” Fawcett said. “It’s not just the engineers that get to play with this cool tool. It can pay dividends across the organization.”

Intelligent digital twins can be used by salespeople to perform lease validations and to identify revenue opportunities. Engineering teams can eliminate site visits with access to complete structure data, including high-resolution photos and versatile 3D models. Construction teams can use it to streamline information flow to support actions from acquisition to close-out. Maintenance and operations teams can use it to capture more accurate asset data to support modification, repair and regulatory requirements.

To further increase the quality of the digital twin, 5×5 Technologies developed a standard procedure for flying a drone around a cell tower that allows the capture of optimal images to ensure the 3D model is extremely accurate, according to Carr. Additionally, a digital twin production pipeline was created, which includes a set of software tools and automation that is applied to convert the tower images into the digital twin. Once the digital twin is created, it is enhanced with AI and machine learning.

“By putting all those things together, we get a couple of important values. One is a very high-fidelity digital twin, which customers can rely on for measurements and analytics. And second, is a procedure that minimizes the need for a re-fly of the tower, which is expensive and time-consuming,” he said.

Carr said he can move around the resulting 3D computer graphics and measure it as if he were putting a tape measure on the actual tower, so that he can do reliable maintenance plans, upgrade plans and know exactly where, for example, the 5G gear is going to be added to a tower. So, when the tower crews get on the site, there are no surprises.

“We think of the digital twin as being the ground truth that our customers can trust,” Carr said. “What that means to us is that when I interact with the twin — either through our visualization tools, or through our analytics interfaces, and even our enterprise services — the data I am seeing is as accurate as if I was on the structure itself.”

In the end, the software makes it easy to take measurements of the tower or to find defects or to identify the equipment on the structure, which allows the tower company to know what’s up on the tower and what needs to be changed.

“I want the computer to do the work, so our customer doesn’t have to. So that they can focus on maintenance planning and revenue optimization, not trying to figure out what’s on that tower,” said Carr.

For more information about 5×5 Technologies, visit https://www.5×5.ai.

By J. Sharpe Smith Inside Towers Technology Editor

Reader Interactions