On track to double its size by 2025, StressCrete’s footprint has multiplied, with manufacturing facilities in five North American locations. The company is on a mission to “bring utility to communities,” says van Vliet. StressCrete produces an extensive line of high-performance LED decorative outdoor lighting fixtures, spun concrete and metal poles, plus pole arms, accessories, bollards and site amenities. It works across several industries, including municipalities, power distribution and transmission, electrical and communications, and sports lighting.

Already well-versed in street furniture, StressCrete saw an opportunity in telecom when wireless infrastructure started being deployed on light poles and lampposts. As many in the industry can attest, wireless infrastructure is not always welcomed with open arms. Resistance to change is not uncommon, thanks to aesthetic concerns and misnomers about the actual technology.

“We’re used to that discussion,” says van Vliet. “As a pole manufacturer, we understand the needs of municipalities, utilities and the people we’ve been working with. We understand the standards of these towns that we’ve been servicing for 20 or 30 years.” According to van Vliet, when a telecom enters the picture, StressCrete “can be very helpful” in streamlining and expediting deployments.

“It comes down to the psychology of ‘just noticeable difference,’” says Mitchell Fasken, the StressCrete Smart Infrastructure Sales Rep. Rather than replace existing structures with completely revamped pole designs — which would be immediately recognized by residents — StressCrete can customize its decorative pole products to accommodate 5G technology.

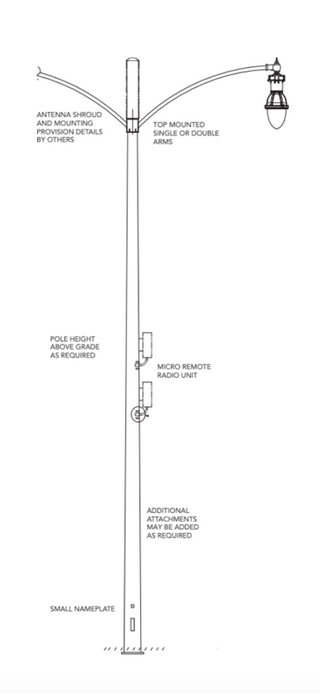

StressCrete offers two material options when it comes small cell pole products: concrete and metal. The spun concrete pole series is inclusive of multiple models, each allowing custom, discrete, and seamless integration of 5G small cell technology, regardless of the implementation hardware or carrier. “Our minimal deflection is important to ensure antennas and radios are not moving out of alignment,” says van Vliet, an imperative component of carrier network quality.

The tapered octagonal and tapered round poles are the most popular concrete options, according to Fasken, but StressCrete can tailor its products to individual needs. Concrete may be extremely dense, but its use applications aren’t as rigid as you might think. “We’re able to take our existing concrete product specifications and because we’re a made-to-order company, we’re able to change the design, or add elements to those pole designs to make them small cell compatible,” explains Fasken.

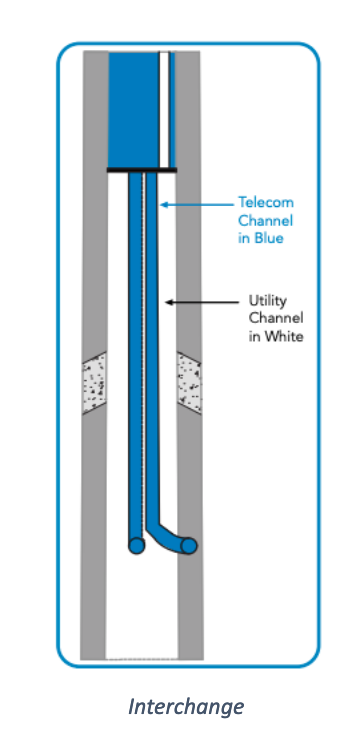

The spun concrete produces a hollow raceway within the pole, providing a smooth conduit for electrical cables and embedment capabilities, optimal for Smart City deployment projects. The Interchange, or telecom and utility pole dividers, are designed to create harmony between the Utility and the Telecom companies using the pole. The Interchange pole divider allows the utility to own the raceway of the pole below the divider, and then own conduit inside the raceway above the divider. Conversely, the telecom owns conduit access below the divider, and the entire pole raceway above the divider.

According to StressCrete, a common roadblock for small cell deployments on street fixtures is the need for separate raceways due to safety regulations. As a result, some telecom companies will run their fiber and power on the outside of poles, opening the door to aesthetic and security issues. The Interchange creates separate raceways for both parties, while maximizing the amount of raceway required for each party at different heights inside the pole. “You wouldn’t think concrete, when you think telecom poles, but it’s actually very applicable to the technology,” says van Vliet.

The poles meet ASTM and CSA standards. A lifetime warranty speaks to the durability of the product. “There’s a reason why bridges are built from concrete,” says van Vliet. These poles are built to withstand the elements and can still be customized to meet customer specifications, including choice of finishing. “It’s a pretty robust product.” When you have thousands of dollars’ worth of equipment being integrated into a structure, a solid foundation is key.

Alternatively, the King metal small cell pole is StressCrete’s “off the shelf,” product, according to Fasken. It’s used by wireless network operators, tower companies, as well as utilities and municipalities. With a 10-inch, non-tapered diameter, the King metal small cell pole has the strength, size and capability of holding small cell equipment with multiple antennas.

The inner raceway of the pole has two separate U-channels, designed to create separate sections of the pole for power access for the utility’s street light fixtures. It can hold up to two streetlight arms and fixtures. StressCrete Group says this is a common solution for mass-standardized deployment. It may not be concrete, but it’s still sturdy. “It’s designed for coastal windspeeds,” says Fasken. “In our strength test, it went close to 1.5x what we had initially designed it for.”

According to van Vliet, StressCrete’s adaptable poles will be the backbone for Smart City technology deployment, from intelligent lighting solutions to electric vehicle charging stations. “We’re going to see a lot more Smart City deployment,” says van Vliet. “We’ve seen a little bit. We’ve seen some pilots, but there hasn’t been scale. That should come in the next few years.” Working with communities at every level to develop relationships is the only means to make way for potentially life-changing technologies.

“It’s about forming partnerships, because ultimately, it’s about enhancing the communities that we’re serving,” says Fasken, citing a successful project in Detroit. The city was struggling. Sixty percent of the city’s lights were out, and a tanking economy sparked a mass exodus. StressCrete Group was part of a metropolitan overhaul and contributed to the lighting immersion. While this particular instance occurred in an adjacent industry, it exemplifies how something so seemingly simple as pole structures, can reinvigorate the livelihood of a community.

For more information about StressCrete Group, visit https://www.scgrp.com/. For more specifically about its small cell poles and related spec sheets, visit https://www.scgrp.com/products/small-cell-poles.

Reader Interactions